Construction Powered by 3D Printing and Renewable Resources

HempCon 3D

3D printed building elements

Days to assemble home

8

High performance concrete structure

80 MPa

W/m²K of 400mm thick assembly with continouse insulation

0.15

Durable, lightweight and energy efficient building elements

-

Fully customized designs that are strong, durable, and tailored to the needs of each project.

-

Lightweight construction that helps reduce the amount of concrete needed for foundations.

-

Cuts down on steel and material usage by up to 70%, making construction more sustainable and cost-effective.

-

Hempcrete offers a high R-value, ensuring superior thermal insulation and energy efficiency for a comfortable living environment.

Offsite construction

Faster, more efficient construction

Material efficient design

Material efficient topologically optimised designs generated using software.

Concrete reduction

70%

Lighter vs concrete element

50%

Carbon negative construction

Our HempCon 3D absorbs more CO2 (14kg eq. CO2 per m2) than it emits—making it a superior, sustainable choice compared to wood and traditional concrete.

Design Global, Construct Local

Seamless construction with Ekotekt’s CAD-to-CAM process.

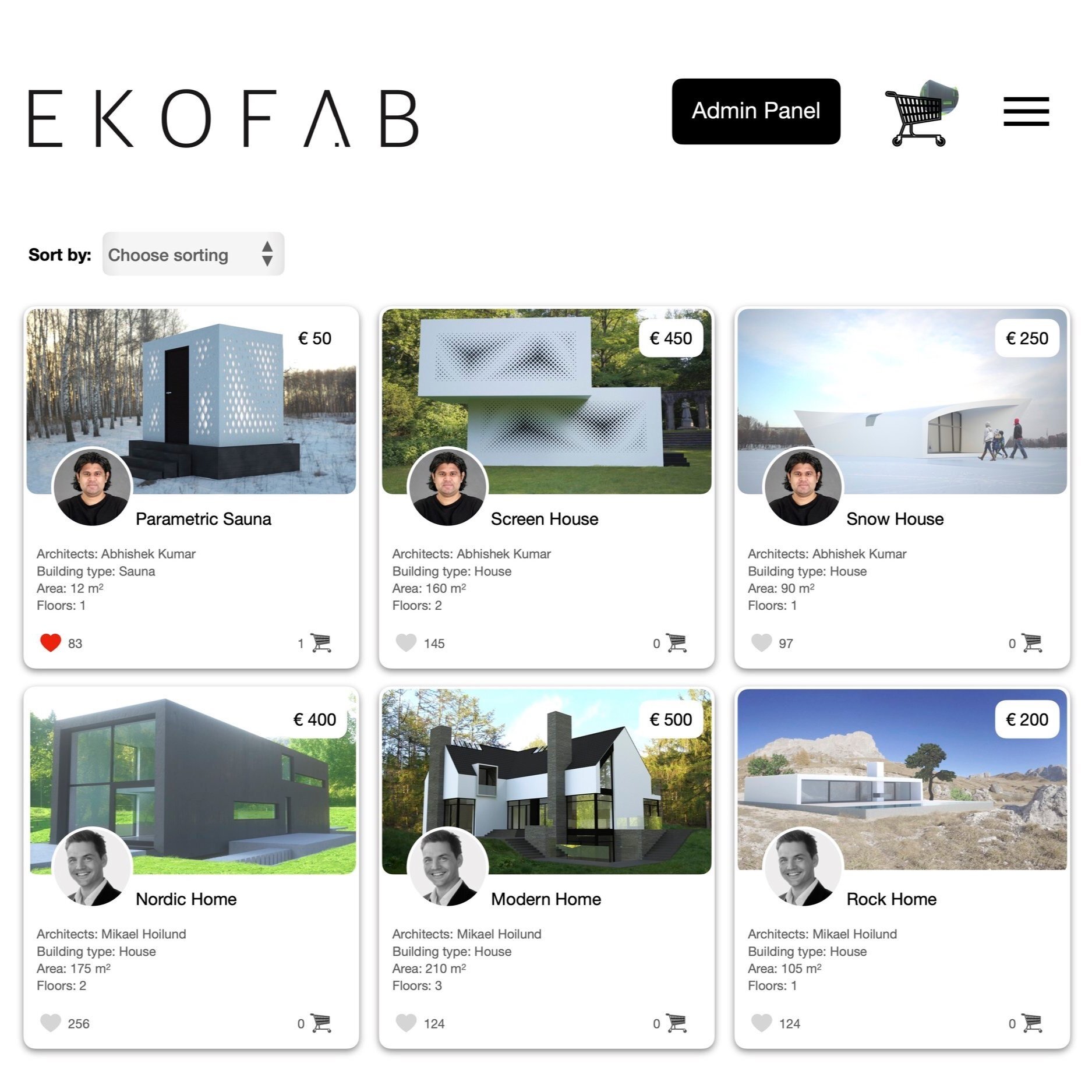

EKOFAB Design Marketplace

At Ekotekt, Ekofab is our innovative platform that connects global architects with cutting-edge technology to bring sustainable designs to life. By turning architectural ideas into 3D print-ready solutions, Ekofab makes construction faster, smarter, and more sustainable.

-

With Ekofab, architects can design projects anywhere in the world. Our platform enables you to work on global projects while ensuring local compliance and seamless integration with digital manufacturing. Expand your portfolio and take on projects globally.

-

With Ekofab, your designs are 3D print-ready, allowing for seamless, on-demand construction. This eliminates delays and accelerates the transition from design to build, saving time and improving efficiency.

Patented manufacturing process

The simple and efficient 3D printing process with clay.

-

Clay is much easier to print with compared to concrete. It flows smoothly, without the risk of material clogging in the pipes, unlike concrete, which hardens quickly and can cause blockages.

-

Clay printing allows for easier maintenance and cleaning of the printing equipment, avoiding the issues of hardened concrete clogging pipes and machinery.

-

Clay is widely available, abundant, and sustainable, making it a perfect choice for large-scale 3D printing without resource constraints.

-

Unlike concrete, which can be difficult to control during printing, clay is a material that builders and architects are familiar with, making it easier to work with and ensuring consistent results.